In the modern world, weighing systems have emerged as a crucial component in waste management and recycling. Accurate weighing of waste materials not only aids in keeping track of costs and efficiency but also helps in recognizing waste as a valuable resource. Let’s delve deeper into the importance and types of waste management weighing solutions.

The Importance of Weighing Systems

Waste is no longer merely an environmental concern, it’s a potential resource. From monitoring waste collection to tracking inputs and outputs during materials recovery, weight information is key. Such data is vital whether the process involves making products for commercial gain, disposing of waste, or creating energy from waste.

In industries where recycling and waste management are emphasized, using appropriate Waste Management Weighing Solutions becomes pivotal for optimum function, ease of use, and profitability.

Waste Weighing Equipment: The Four Pillars

Waste weighing equipment typically falls into four categories: rail scales, truck scales, floor scales, and forklift scales.

Rail Scales

Ideal for weighing heavy industrial commodities, rail scales can be configured for static weighing and come in the form of modular decks spaced to match the distance between the train’s wheels. The scales are connected to digital recorders and display systems for easy reading and storage of weight measurements.

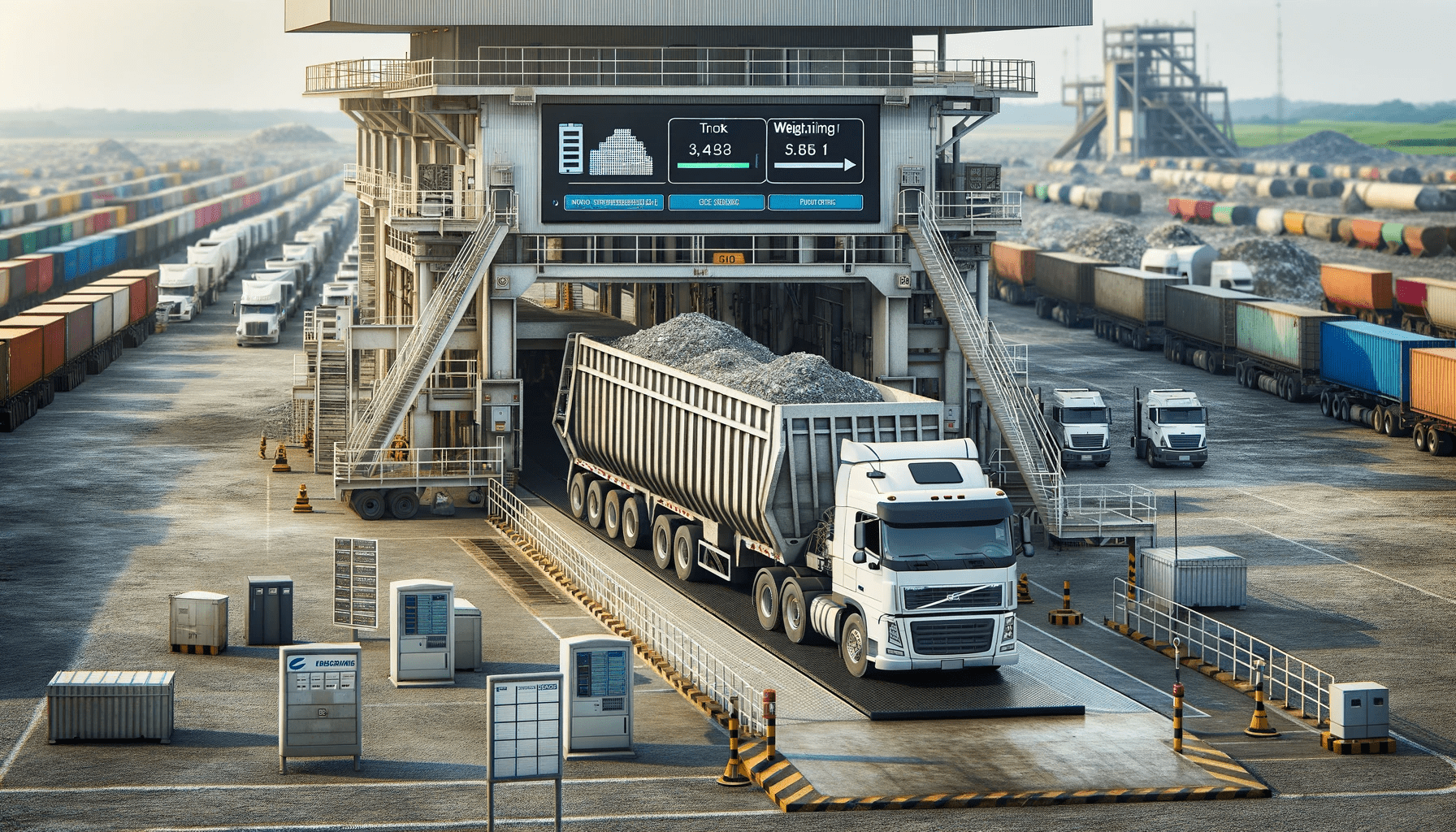

Truck Scales

As versatile weighing solutions for waste or recycling, truck scales can weigh the vehicle upon its arrival or departure from the business location. Each transaction can be monitored and the weight of waste accurately measured. They are built to withstand extreme weather conditions and weight shocks. Truck scales can also ensure vehicles are filled to capacity without unsafe and illegal over-loading.

Floor Scales

Installed on the top level of a flooring surface or in a pit, floor scales allow for the weighing of waste by transporting loads directly onto the scale. They determine weights with high accuracy and precision, making them a reliable choice for businesses.

Forklift Scales

Forklift scales allow users to carry and transport bundled or bound waste while measuring their weight. They provide real-time data and transport waste simultaneously, thus saving time and money.

Maintaining Accuracy in Weighing Equipment

Proper maintenance services of your weighing systems are recommended to keep them accurate. Factors such as wear and tear on components, rough usage, environmental changes, and buildup under the scale can affect the scale beyond calibration.

Legal-for-Trade Weighing Solutions

A scale system capable of legal-for-trade weighing is a valuable asset in the waste industry. It not only ensures the legality of your operations but also serves as a badge of reliability, ensuring customer satisfaction, precise billing, and accurate inventory records.

Vehicle and Axle Scales

Vehicle and axle scales, including weighbridges and truck scales, can be used to weigh virtually any material. These scales ensure that trucks are loaded to the ideal weight, avoiding costly fines and premature vehicle wear due to excessive loading.

Unattended Terminals for Increased Efficiency

Unattended weighing terminals enable drivers to complete weighing transactions 24/7, without leaving their cab. This results in reduced operating costs, extended hours of availability, and improved health and safety.

Rail Scales for Complete Data Tracking

Rail scales can be configured for static or in-motion weighing and can provide readings for individual axles and even wheels.

Floor and Bench Scales for High Accuracy

Floor and bench scales are capable of weighing goods with high accuracy. While floor scales can be placed at a central location within a waste sorting facility, bench scales are ideal for facilities that deal with high-value waste streams such as e-recycling.

Forklift Scales for Efficient Operation

Forklift scales allow users to weigh bundled and palletized recycled materials en route. They expedite operations by enabling forklift drivers to take commodities directly to storage upon delivery while accessing real-time data.

Digital Weight Indicators for Accurate Readings

Digital weight indicators display the weight reading used in conjunction with the scale itself. They collect, store, and communicate weight data, and more advanced digital indicators use wireless communications to transmit data to back office systems.

Regular Service, Calibration, and Maintenance

Regular preventative maintenance of your equipment keeps it working at maximum efficiency and reduces the likelihood of costly emergency breakdowns. This directly impacts the cost of ownership, leading to fewer service trips, less downtime, and less money spent over the life of the scale.

In conclusion, Waste Management Weighing Solutions are a critical aspect of waste and recycling industries, ensuring accurate tracking, efficient operations, and overall profitability. The appropriate system, backed by regular maintenance and smart software, can result in optimal waste management and an effective recycling process.